- Products

- Automatic Pipe Welding Machines

- Piping Prefabrication Automatic Welding Machine(FCAW/GMAW)

- Piping Prefabrication Automatic Welding Machine(SAW)

- Piping Prefabrication Automatic Welding Machine(GTAW)

- Piping Prefabrication Automatic Welding Machine(MIG)

- Piping Cantilever Automatic Welding Machine(FCAW/GMAW)

- Piping All-position Automatic Welding Machine(FCAW/GMAW)

- Piping Cantilever Automatic Welding Machine(SAW)

- Piping Cantilever Automatic Welding Machine(GTAW)

- Piping All-position Automatic Welding Machine(GTAW)

- Portable Piping Automatic Welding Machine(FCAW/GMAW)

- Thick-wall Piping Automatic Welding Machine(SAW)

- Slip-on Flange Automatic Welding Machine(FCAW/GMAW)

- Welding Elbow Automatic Welding Machine(FCAW/GMAW)

- Welding Elbow Automatic Welding Machine(SAW)

- Thick-wall Pipe Automatic Welding Machine

- Piping Prefabrication Automatic Welding Machine (FCAW/GMAW) PPAWM-24A8

- Piping Prefabrication Automatic Welding Machine (FCAW/GMAW)

- Multifunction Automatic Pipe Welding Machine (TIG+MIG+SAW, Cantilever Type)

- Multifunction Automatic Pipe Welding Machine (TIG+MIG+SAW, Press Roller Type)

- Automatic Magnetic Pulse Pipeline Welding Machine

- Piping Prefabrication - Workstation

- Piping Automatic Welding Workstation(A-type)

- Piping Automatic Welding Workstation(B-type)

- Piping Automatic Welding Workstation(C-type)

- Piping Automatic Welding Workstation(D-type)

- Piping Automatic Welding

Workstation(E-type) - Piping Automatic Welding Workstation(F-type)

- Pipe Bevel Machining

Workstation(A-type) - Pipe Bevel Machining

Workstation(B-type) - Pipe Bevel Machining

Workstation(C-type) - Piping Radiographic Test

Workstation(A-type)

- Piping Prefabrication Production Line

- Piping Prefabrication Production Line (Fixed Type)

- Transportable Piping Prefabrication Production Line

- Double-purpose Piping Prefabrication Production Line

- Pipe Bevel Machining Flow

Line(A-type) - Pipe Bevel Machining Flow

Line(B-type) - Pipe Bevel Machining Flow

Line(C-type)

Add: No.866 Xinyan Road, Maogang Town, Songjiang District, Shanghai City, China

Post Code: 201607

Tel: +86-21-57574707

+86-21-57570147 Ext.8288

+86-21-57570147 Ext.8266

+86-21-57570147 Ext.8268

+86-21-57570147 Ext.8259

Mobile (WhatsApp):

+86-13611747409

+86-15618362986

Fax: +86-21-57574023

E-mail: vip@qiansh.com

okey@qiansh.com

piping@qiansh.com

Skype: cnwilliamqi

Contact Person: William Qi

Skype: cnqspt

Contact Person: Gaven Hwang

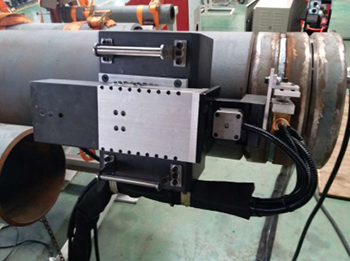

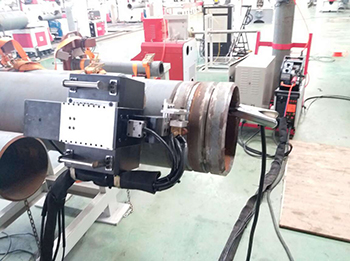

Automatic Magnetic Pulse Pipeline Welding Machine

Parameters

Product type: PAAWM-06A

Automatic magnetic pulse pipeline welding machine is composed of power supply, wire feeding system, magnetic welding trolley and welding control system, etc.

Applicable pipe diameter: 》DN150

Pipe thickness: 4-30

Applicable materials: CS, AS, SS and Cryogenic Steel

Applicable welding joint: Various pipe butt welding joint, such as pipe-pipe, pipe-elbow, pipe-flange, etc. .

Magnetic welding trolley

Driving wheel: Magnetic wheel

Wheel set suction: 》50KG

Driving system: DC servo motor drive

Speed: 50-750MM/MIN, stepless speed control

Rotation accuracy: Rotating a cycle on the DN150-DN400 seamless tube with a center deviation less than 0.5MM

Driving impulse: When rotating downward on the seamless pipe, the driving impulse is less than 0.5mm.

Adjustment system: As our patented product, welding torch stepper motor is used to adjust the position to right and left, up and down.

Oscillating system:As our patented product, welding torch stepper motor adjusts the oscillation to right or left.

Features

The workpiece (pipe) is fixed. Welding trolley around the workpiece rotates to achieve full-position automatic welding of pipeline.

Welding process: Automatic magnetic pulse pipeline welding machine uses high-efficiency and low-cost gas to protect welding.

- Products

- Long-distance Pipeline Construction Equipment

- Pipeline Internal-expanding End Beveling Machine

- Piping Internal Pneumatic Pipe Line-Up Clamp

- Piping All-position Automatic Welding Machine(FCAW/GMAW)

- Pipe Cutting Equipment

- Pipe CNC Cutting Band Saw Machine

- Pipe CNC Profile Cutting Machine

- Pipe Cutting Band Saw Machine

- Pipe Beveling Machines

- Fixed-type Highly-efficient Pipe Cutting and Beveling Machine

- Fixed-type Radial Pipe End Beveling Machine

- Fixed-type Axial Pipe End Beveling Machine

- High Speed Pipe and Fittings Bevelling Machine

- Orbital Pipe Cutting and Bevelling Machine

- Portable Pipe Bevelling Machine

- Movable Internal-expanding Pipe End Beveling Machine

- Movable Orbit-type Pipe Cutting and Beveling Machine

- Roller-bed-type Pipe Flame Cutting and Beveling Machine

- Roller-bed-type Pipe Plasma Cutting and Beveling Machine

- Roller-bed-type Pipe High-pressure Water Cutting and Beveling Machine

- Magnetic Pipe Flame Cutting and Beveling Machine

- Fixed-type CNC Pipe End Beveling Machine

- Orbit-type Pipe Flame Cutting and Beveling Machine

- Fixed-type Two-direction Pipe End Beveling Machine

- Other Pipe Processing

Machines - Piping Welding Displacement Machine

- Pipe Logistics Transportation System for Band Saw Machine

- Pipe Logistics Transportation System for End Beveling Machine

- Pipe Logistics Transportation System for Cutting and Beveling Machine

- Pipe Logistics Transportation System for Bevel Cutting Machine

- Pipe Logistics Automatic Transportation System

- Mechanical Type Pipe Cutting Length-Measuring System

- Slip-on Flange Fast Fitting-up Machine

- Piping Prefabrication Fast Fitting-up Machine

- Pipe Prefabrication Software Program

- PDSOFT-Pipe Designing and Drawing

- PDSOFT-Pipe Processing Management

- Management System of Pipeline Prefabrication

USA

USA Britain

Britain India

India Español

Español Português

Português